You’ve invested in beautiful packaging that catches customers’ attention on the shelf. But once they take your product home, that’s often where your relationship ends. Despite your packaging looking great, it can’t tell the full story of your brand.

Most businesses want their customers to know more about their product: detailed usage instructions, ingredient sourcing stories, sustainability credentials, or current promotional offers. However, packaging space is limited, and you need to balance compelling design with information density to avoid overwhelming customers. When regulations change or promotional campaigns end, reprinting thousands of packages becomes costly and wasteful.

A simple QR Code on your packaging can solve all these challenges. It’s compact, interactive, and can connect customers to any content medium — tutorials, loyalty program forms, or dynamic web content that you can update without reprinting.

This guide shows you how to design product packaging with QR Codes that customers actually want to scan. You’ve invested in beautiful packaging. But is it doing enough?

Table of contents

- How QR Codes on packaging transform the way you share product information

- How do QR Codes on packaging turn curiosity into customer action?

- How to create and manage QR Codes across packaging types

- Turn your product packaging into an instant product information hub

- Frequently asked questions

How QR Codes on packaging transform the way you share product information

A well-designed product packaging helps the product move off the shelves. But adding a QR Code to it helps you connect and measure post-purchase engagement as well.

1. Provide consumers with complete product information instantly

With limited space on a label, it’s often impossible to share every detail a curious consumer might want to know. In fact, research shows that 79% of shoppers prefer products with QR Codes that offer additional information. You can use this as a touchpoint to share more details about ingredients, usage instructions, or sourcing without compromising the package design.

2. Strengthen trust through transparency

QR Codes on product packaging can boost consumer trust by up to 40% as they enable consumers to verify the product’s authenticity. Customers are increasingly conscious of a product’s origin and authenticity, and QR Codes offer a simple way to build confidence. A quick scan can reveal a product’s origin and confirm its certifications. This transparency is a key factor in building a loyal customer base.

3. Cut costs and reduce waste with digital content

Printing extensive leaflets and manuals adds to packaging costs and contributes to waste, especially for businesses that use QR Codes to run promotional campaigns or have regulations that change frequently.

QR Codes offer a sustainable and cost-effective alternative by moving that content online. In fact, dynamic QR Codes can be updated at any time, which helps brands avoid the significant expense of reprinting materials due to a minor change in product information.

4. Analyze consumer interactions to make smarter decisions

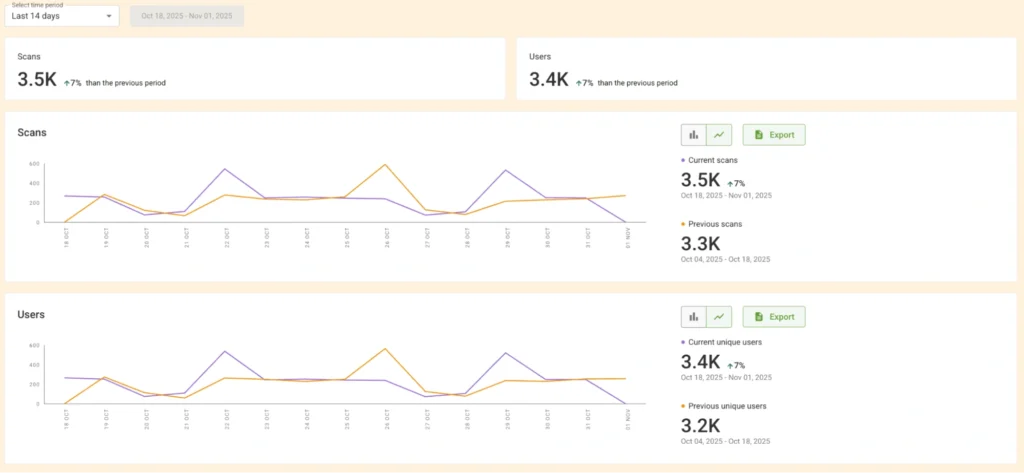

Any good marketing campaign is successful only if it is measurable. Adding trackable QR Codes to your product packaging helps you use scan data to determine how users interact with your QR Codes, the optimal placement for the QR Code, and more.

61% of users scan a QR Code on a product after purchasing it. You can track metrics such as scan volume, time of day, geographic location, and the device used, offering insights into customer engagement. Furthermore, 95% of businesses report that QR Codes help collect valuable first-party data, which can help in tailoring promotions and designing more relevant post-purchase experiences.

Now that you’ve seen how QR Codes help address label limitations, transparency needs, and data gaps, it’s time to look at what happens after the scan.

How do QR Codes on packaging turn curiosity into customer action?

Sharing information is easy. Getting customers to act on it? That’s the real trick. You want your QR Codes to drive engagement, from following tutorials to registering warranties.

Let’s see how QR Codes on packaging can deliver value at every stage of the customer journey.

1. Share detailed manuals and assembly guides

A QR Code on the packaging can link customers directly to digital resources. It is beneficial for products that require assembly or have complex instructions.

A scan can lead to:

- Video tutorials or step-by-step video guides

- Digital manuals or easy-to-navigate PDF guides

- FAQs and troubleshooting

This approach significantly improves the customer experience by reducing frustration. For example, electronic businesses can link QR Codes to set up videos, whereas furniture brands can use them to connect customers to interactive assembly videos. These videos enhance the post-purchase experience for new customers and reduce the reliance on support channels.

2. Offer ingredient and allergen information

Today’s consumers are more conscious than ever about what they put in and on their bodies. QR Codes enable brands to be transparent by providing detailed information that doesn’t fit on a standard label, especially for individuals with allergies or specific dietary requirements.

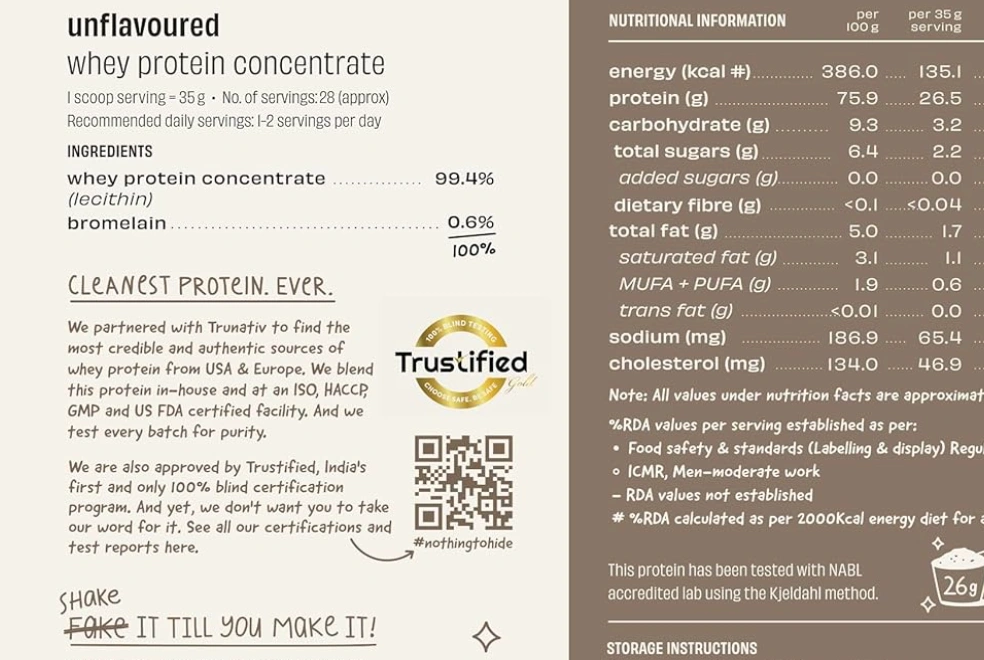

Brands such as Nestlé use QR Codes to comply with labeling standards and share in-depth ingredient data. Some companies take it a step further; for example, the protein bar brand The Whole Truth uses QR Codes to show customers the lab test results for its ingredients.

3. Promote sustainability with recycling instructions and eco-labels

QR Codes can guide customers on how to manage waste and share information on their sustainability efforts responsibly. For instance, Colpac, a food packaging company, uses QR Codes on its packs to share recycling and composting instructions in multiple languages, helping customers dispose of packaging correctly. Similarly, Metsä Board integrates QR Codes into its paperboard packaging to direct users to detailed recycling guides and material data, simplifying proper disposal and promoting circular use.

A QR Code scan can also direct consumers to information on the product’s carbon footprint and the brand’s sustainability initiatives, and details about the eco-friendly materials used and the company’s commitment to the environment.

4. Authenticate products to fight counterfeiting

When it comes to luxury purchases, electronics, and pharmaceuticals, counterfeit goods are a genuine concern. By placing a unique product info QR Code on each item, brands can empower consumers and retailers to verify the authenticity of their purchase.

When a customer scans the QR Code, they are taken to a secure page that confirms the product’s legitimacy. For example, Louis Vuitton has integrated QR Codes into their products, with which consumers can verify the authenticity of their purchases.

5. Collect feedback, register warranties, and boost customer retention

QR Codes offer a seamless way to manage post-purchase activities, such as warranty registrations and customer feedback. Instead of asking customers to fill in and mail a paper form, a quick scan is all it takes. Industries such as electronics, appliances, and automotive use them to replace lengthy forms with quick scans.

Once collected, this data helps brands streamline support, identify product issues early, and build stronger customer relationships through personalized follow-ups and targeted offers.

Once you understand how QR Codes enhance engagement, the next step is execution.

Before you start printing or applying them to your packaging, you need a plan: one that aligns your design, content, and tracking.

How to create and manage QR Codes across packaging types

Before you print a single label, you need a clear strategy. QR Codes are most effective when they are thoughtfully planned, generated, and managed. Here are six practical steps to integrate codes into every layer of your packaging workflow.

Step 1: Plan before you print

Not every QR Code serves the same purpose. Some meet compliance requirements, others drive engagement or conversions, and some authenticate products. Knowing your goal early helps you choose the right type of QR Code, content strategy, and tracking setup.

You need to make a few decisions before creating your QR Code for product information:

A. Decide what is on the pack vs. what is on the QR Code

A good way to decide what belongs on the packaging versus behind the QR Code is to ask:

- Does this information need to be immediately visible? Keep essentials such as safety details, legal disclaimers, and regulatory text on the pack.

- Does it enhance the experience but take up space? Move optional content, videos, recipes, brand stories, or sustainability efforts behind the QR Code.

This simple filter helps you strike a balance between clarity on the label and depth through digital access, ensuring your packaging remains both compliant and engaging.

B. Choose the right packaging level for your QR Code

Packaging isn’t one-size-fits-all. Each layer offers different opportunities for using QR Codes:

- Primary packaging refers to the container that is in direct contact with your product, such as a bottle, pouch, or tube. It’s ideal for compliance, authenticity, or consumer-facing content.

- Secondary packaging is the outer box or sleeve. Use this space for marketing messages, tutorials, or loyalty campaigns.

- Tertiary packaging refers to cartons or shipping boxes. It’s best suited for supply chain tracking or internal logistics.

Knowing which layer will carry your QR Code ensures the proper visibility and scanning experience.

C. Define your stock keeping unit (SKU) strategy

Decide how granular your QR Code tracking should be. You can either:

1. Use a single family QR Code for all products in the same line. It directs all customers to the same page, making it ideal for marketing campaigns or loyalty programs.

Ideal for FMCG, cosmetics, beverages, or lifestyle brands running seasonal promotions or directing customers to a particular landing page. It keeps things simple and cost-effective while maintaining consistent brand messaging.

2. Use SKU-specific (serialized) QR Codes for individual products or batches. Each unit gets a unique code, which allows for advanced use cases such as traceability, anti-counterfeiting, and targeted recalls.

Best suited for pharmaceuticals, electronics, luxury goods, or food brands.

D. Assign ownership and governance

Finally, decide who owns your QR Code strategy, from content updates to technical monitoring. Assign clear responsibilities for:

- Content ownership: Who maintains the landing pages and updates information?

- Update cadence: How often should you refresh the content behind each QR Code?

- URL health monitoring: Who ensures that every code still leads to a valid page?

- SKU-to-QR Code mapping: How will you document which codes belong to which products?

Step 2: Generate your QR Code

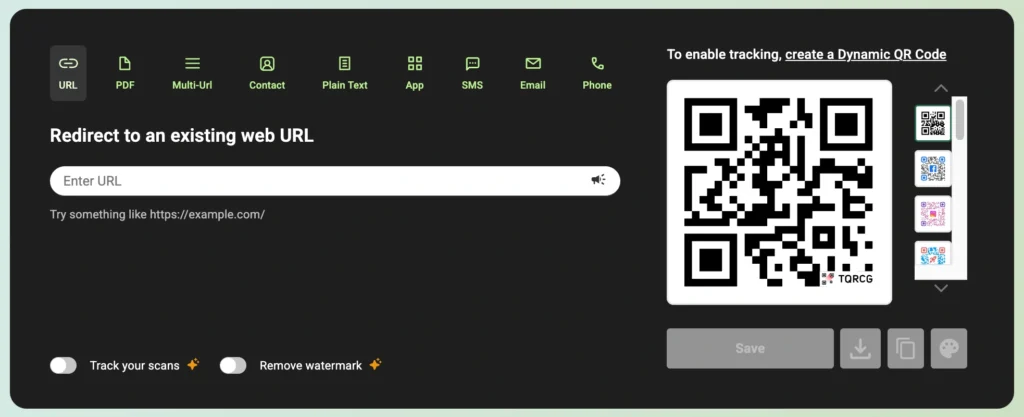

Once your plan is in place, it’s time to bring it to life. Head to The QR Code Generator, where you can quickly create a QR Code that fits your packaging goal.

Choose what you want your customers to view after scanning and the kind of experience you want to deliver:

| Type | What it does | Best used for |

| URL QR Code | Links directly to any web page | Driving engagementSharing detailed product informationSustainability updatesBrand storytelling |

| Video QR Code | Opens a hosted video via a URL | DemonstrationsAssembly guidesTutorials |

| Audio QR Code | Plays an audio file or message | Accessibility supportMultilingual instructionsGuided experiences |

| PDF QR Code | Displays or downloads a PDF file | Compliance documentationUser manualsProduct certificatesBrochures |

| Plain Text QR Code | Displays a short text when scanned | Internal trackingSKU/Factory ID displayBatch or serial number verification |

| Form QR Code | Opens a form for data collection. | FeedbackProduct registrationWarranty activationSurveys |

| Call QR Code | Initiates a phone call to a preset number | Customer supportService requestsUrgent assistance lines. |

Once you’ve chosen your QR Code type, you need to convert it to a dynamic QR Code so that you can edit, track, and customize your QR Code later.

Step 3: Design and prepare your QR Code for print

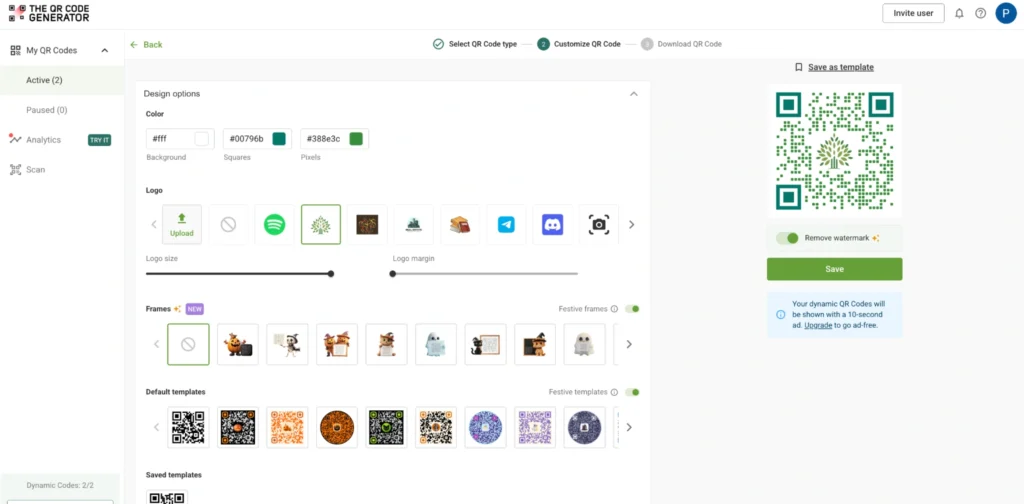

Once you’ve decided what your QR Code will link to, it’s time to design it for your product packaging. The goal here is twofold: make it instantly scannable and visually consistent with your brand.

While designing your QR Code, you need to ensure that the colours match your product packaging. You can also opt to add a QR Code logo or a frame to enhance the customer’s trust.

Just ensure there’s enough color contrast, darker codes on a light background scan best.

💡 Pro tip: Since you need to print the QR Code on your packaging, you need to ensure you’ve chosen the correct QR Code format and size of the QR Code. Typically, the SVG format is most suitable, but the size of the QR Code depends on the type of product. Additionally, it’s important to choose high-resolution printing (at least 300 dpi), avoid matte coatings that blur details, and test scannability after printing.

Step 4: Optimize the post-scan experience

Once your customer scans your QR Code, it should lead to a relevant and mobile-friendly destination.

Most users scan using mobile devices, so your landing page, form, or video must load fast and display perfectly on small screens. Compress large images, shorten load times, and keep buttons or forms thumb-friendly on the screen.

One of the best QR Code security practices to follow includes using a secure HTTPS link to reassure users that the QR Code leads to a legitimate brand page. Add brand identifiers (such as your logo or domain name) on the landing page to reinforce authenticity. If you’re sharing promotions or forms, clearly mention what data is collected and why.

Step 5: Test and validate QR Codes

Before printing packaging for all your products, consider creating a prototype in its final size and placement to test the design. Test the prototype with multiple devices, using both iOS and Android phones.

Here’s a quick checklist of all the parameters you need to test:

1. Check scanning distances:

- Hand-held range: 30 – 40 cm

- Shelf-view range: 1 – 1.5 meters (for larger packaging)

2. Test under different lighting conditions, such as bright retail lights, daylight, and low light.

3. Inspect contrast and clarity. Make sure the code remains sharp and readable on the printed surface.

4. Evaluate the scannability on curved or textured surfaces, such as bottles, tubes, or flexible pouches.

If you notice any issues with glare, smudging, or scanning delays, adjust the design, reprint, and test again before final production.

With The QR Code Generator (TQRCG), you can enable QR Code error correction levels to preserve scannability even if part of the code is slightly smudged or bent. It is especially valuable for products that are subject to wear and tear during shipping or handling.

Step 5: Perfectly place your QR Code on your packaging

Choose a placement that feels intentional. For example, place it near your product story, nutrition facts, or usage instructions so it complements existing content.

Avoid corners or folds where the surface curves, and maintain a quiet zone (at least 4× the width of a QR Code module) to ensure scannability. Of course, not all packaging follows the same rules. Each industry has its own requirements, customer expectations, and design constraints.

Here’s how to adapt your QR Code placement and content strategy based on your specific product category.

| Industry | Best placement | Content focus |

| Food and beverage | Near nutrition facts, ingredient list, or recycling information panel | Ingredient sourcing, allergen clarity, recipe content, and localized recycling instructions |

| Cosmetics and personal care | On the product side, near usage instructions or promo label | Ingredient origin, safety certifications, how-to videos, and patch test instructions |

| Pharmaceuticals and supplements | Besides batch/lot numbers, dosage information, or regulatory marks | Batch verification, dosage guidance, safety data sheets, and authenticity checks |

| Electronics and industrial goods | On side or back panels, or inside flap for smaller items | Digital manuals, setup tutorials, firmware updates, and warranty registration |

Step 6: Analyze and optimize performance

After your QR Codes go live, the data you collect can reveal powerful insights about customer engagement and packaging effectiveness.

With TQRCG’s dynamic QR Codes, you can monitor:

- Number of scans to gauge interest or campaign reach

- Time and location data to identify high-engagement regions

- Device types to optimize content formats

- Peak scan periods to refine timing for promotions

💡 Pro tip: If scan rates drop, A/B test your QR Codes to experiment with different placements, CTAs, or linked content to see what drives more engagement. Multi-QR Code campaign management helps you compare performance across versions, products, or regions, making it easier to identify what’s working and optimize accordingly.

For example, if a “Scan for discount” code drives more engagement in festive months, replicate that incentive during other shopping seasons.

Turn your product packaging into an instant product information hub

You’ve seen how QR Codes can turn static packaging into an interactive channel that instantly shares product details, tutorials, and authenticity information. Start small by adding a QR Code to one product line, track its scan performance, and then refine your approach based on real engagement data.

Over time, you’ll learn which content types, such as usage guides, ingredient details, or loyalty rewards, resonate most with your audience. The best part? You don’t need complex tools or a big tech setup to make your packaging a seamless source of product information.

With The QR Code Generator (TQRCG), you can:

- Create unlimited static and two free dynamic QR Codes that never expire.

- Customize your QR Codes with logos, frames, and brand colors for on-brand packaging.

- Edit links anytime with dynamic QR Codes.

- Track performance in real time with scan analytics for data-driven insights.

- Manage multiple codes across product lines with ease and clarity.

Get started by creating a free QR Code!

Frequently asked questions

For most product packaging, dynamic QR Codes are the smarter choice. They allow you to update links at any time without reprinting, track scan activity, and run multiple campaigns from the same printed code. Static QR Codes, on the other hand, are fixed once printed and are best suited for permanent, unchanging information, such as compliance documents or serial numbers.

As a general guideline, your QR Code should be at least 2 × 2 cm (0.8 × 0.8 in) for close-range scanning, and larger if your product is viewed from a distance (for example, on shelves). Always test print samples and scan them under real lighting and surface conditions before mass production.

Yes, customization can make your QR Codes more inviting and consistent with your brand. You can add your logo, change colors, or choose a frame with a short call-to-action such as “Scan for details.”

It depends on your goals. If you want to share common content across a product family, using a single QR Code for all SKUs is efficient. But if you want SKU-level tracking, such as measuring engagement by product variant, verifying authenticity, or managing recalls, unique dynamic QR Codes per SKU are ideal.

Start by tracking scan rates, locations, and the time of scans through your QR Code dashboard. Then connect those insights to conversion data in your CRM or Google Analytics using UTM parameters. This helps you see how many scans lead to purchases, registrations, or feedback submissions.